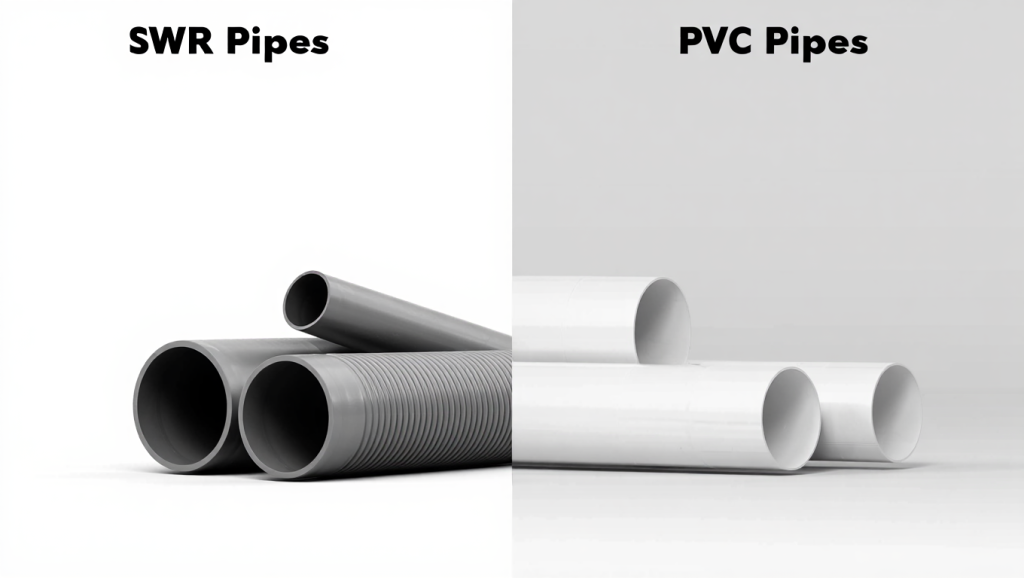

When it comes to designing and implementing effective drainage systems for residential, commercial, or industrial projects, selecting the right type of pipe is a decision that can impact the functionality, longevity, and cost-efficiency of your entire plumbing infrastructure. Two popular options consistently dominate the market: SWR (Soil, Waste, and Rainwater) pipes and PVC (Polyvinyl Chloride) pipes. While both are manufactured from PVC material, they serve distinctly different purposes and possess unique characteristics that make them suitable for specific applications.

This comprehensive guide will explore the nuances of both pipe types, examine their strengths and limitations, and help you make an informed decision about which option is better suited for your drainage requirements. Whether you’re a homeowner planning a renovation, a contractor managing a construction project, or a facility manager maintaining existing infrastructure, understanding these differences is crucial for project success.

Understanding SWR Pipes: The Drainage Specialist

SWR pipes are purpose-built solutions specifically engineered for soil, waste, and rainwater drainage systems. These pipes are manufactured according to stringent industry standards to handle the unique demands and challenges of drainage applications. The term “SWR” itself reveals the pipe’s intended purpose: managing soil discharge from toilets, waste water from sinks and bathrooms, and rainwater from roofs and gutters.

One of the defining characteristics of SWR pipes is their smooth interior surface, which is meticulously designed to prevent blockages and facilitate the easy, unobstructed flow of wastewater, sewage, and rainwater. This smooth bore is critical in drainage applications where solid waste particles, debris, and other materials need to move freely through the system without accumulating or creating obstructions.

SWR pipes are typically available in larger diameters ranging from 75mm to 315mm, making them ideal for handling significant volumes of waste and water that drainage systems commonly encounter. The sizing options allow for proper system design based on the building’s requirements and expected load. These pipes come in different colors, with grey being the most common for drainage applications, though other colors may be available depending on regional preferences and standards.

Key Features and Advantages of SWR Pipes

Specialized Engineering Design: SWR pipes are manufactured with optimal wall thickness specifically calculated for drainage applications. This engineering consideration ensures the pipes can withstand the various stresses they’ll encounter, including external soil pressure when buried underground, the weight of flowing waste materials, and potential impact during installation and building settlement.

Superior Chemical Resistance: Drainage systems regularly encounter harsh chemical environments. Household cleaning products, industrial waste chemicals, acidic substances, alkaline detergents, and naturally occurring acids in sewage can all potentially degrade inferior materials. SWR pipes are specifically formulated to resist these corrosive effects, ensuring long-term integrity and preventing premature failure or leakage.

Optimized Smooth Interior: The interior surface finish of SWR pipes is engineered to minimize friction and prevent the buildup of debris, grease, and solid waste. This smooth bore maintains consistent flow rates over time and reduces the likelihood of blockages that can lead to costly backups and maintenance issues.

Self-Extinguishing Fire Resistance: Safety is paramount in building construction, and SWR pipes incorporate fire-resistant properties that make them self-extinguishing. This means that if exposed to fire, the material won’t continue burning once the flame source is removed, adding an important layer of safety to your building’s infrastructure.

Enhanced Ring Stiffness: When pipes are buried underground or pass through structural elements, they must withstand external loads from soil, concrete, foot traffic, or vehicle weight. SWR pipes are designed with appropriate ring stiffness to resist deformation and collapse under these conditions, ensuring long-term structural integrity.

Effective Noise Reduction: The flow of water and waste through drainage pipes can create significant noise, particularly in multi-story residential buildings where pipes run through walls adjacent to living spaces. The thicker walls of SWR pipes provide superior sound dampening compared to standard alternatives, contributing to a quieter, more comfortable indoor environment.

Understanding PVC Pipes: The Versatile Option

PVC pipes represent one of the most versatile plumbing materials available in the modern construction industry. While they’re also manufactured from polyvinyl chloride—the same base material as SWR pipes—standard PVC pipes are primarily designed and optimized for water supply and distribution rather than waste disposal applications.

The versatility of PVC pipes stems from their ability to handle pressurized water systems, which requires different material properties than gravity-fed drainage systems. PVC pipes come in different schedules, which indicate wall thickness, with Schedule 40 and Schedule 80 being the most commonly used in construction. These schedules correspond to different pressure ratings, allowing designers to select appropriate pipes based on the system’s operating pressure requirements.

PVC pipes are available in an extensive range of sizes from small-diameter pipes for residential water supply to large-diameter pipes for municipal water distribution. They’re typically manufactured in white, cream, or grey colors, with color sometimes indicating the pipe’s intended application or pressure rating depending on regional manufacturing standards.

Key Features and Advantages of PVC Pipes

Exceptional Versatility: PVC pipes excel in multiple applications beyond drainage, including potable water supply, irrigation systems, pool plumbing, chemical transport, and industrial process piping. This multi-purpose capability makes them a popular choice for contractors and builders who work on diverse projects.

Pressure Rating Capability: Unlike drainage pipes that rely on gravity, water supply systems require pipes that can withstand significant internal pressure without bursting or leaking. PVC pipes are specifically designed and tested for pressure ratings, with different schedules offering different pressure capabilities to match system requirements.

Cost-Effective Solution: For general plumbing applications, particularly water supply systems, PVC pipes often represent the most economical choice. Their widespread availability, efficient manufacturing processes, and competitive market dynamics contribute to favorable pricing for non-specialized applications.

Lightweight and Manageable: PVC pipes are significantly lighter than traditional metal alternatives like galvanized steel or copper, making them easier to transport, handle, and install. This characteristic reduces labor costs and physical strain during installation, particularly in larger commercial or industrial projects.

Complete Corrosion Immunity: Unlike metal pipes that can rust, corrode, or develop mineral deposits over time, PVC pipes are completely immune to corrosion. This property ensures consistent water quality and eliminates the risk of pipe failure due to corrosion-related deterioration.

Impressive Longevity: When properly installed and used within their design parameters, PVC pipes can deliver 50 to 100 years of reliable service. This exceptional lifespan makes them an excellent long-term investment for building infrastructure.

Comprehensive Head-to-Head Comparison

1. Primary Application and Design Purpose

SWR Pipes: These pipes are purpose-built exclusively for drainage applications. They’re engineered to handle the specific challenges of transporting sewage from toilets, grey water from sinks, showers, and washing machines, kitchen waste, and rainwater from roofing systems. The design accounts for gravity flow, solid waste transport, and the chemical environment of drainage systems.

PVC Pipes: Standard PVC pipes are optimized for pressurized water supply systems where clean water needs to be pushed through pipes to fixtures and appliances. While they can be adapted for some drainage applications, this represents a compromise rather than an optimal solution.

Winner for Drainage Applications: SWR Pipes without question. Using the right tool for the job ensures optimal performance and longevity.

2. Wall Thickness, Structural Integrity, and Durability

SWR Pipes: The wall thickness of SWR pipes is specifically calculated to handle multiple stresses simultaneously. They must support the weight of waste materials flowing through them, resist external pressure from surrounding soil when buried, withstand occasional impacts during installation or building settlement, and maintain structural integrity over decades of service. This robust construction prevents pipe failure, leakage, and costly repairs.

PVC Pipes: Wall thickness in PVC pipes varies by schedule rating, with thinner walls in lower schedules designed primarily to contain internal water pressure. While perfectly adequate for water supply, these specifications don’t necessarily provide the structural robustness required for demanding drainage applications, particularly in underground installations.

Winner for Drainage Applications: SWR Pipes provide the structural integrity necessary for reliable drainage system performance.

3. Chemical Resistance and Material Compatibility

SWR Pipes: Drainage systems create harsh chemical environments that standard materials might not withstand. Sewage contains naturally occurring acids and bacteria that can degrade materials over time. Household cleaners, including bleach, drain cleaners, and disinfectants, introduce strong chemicals. Kitchen waste includes grease, oils, and food acids. SWR pipes are specifically formulated with additives and stabilizers that resist these chemical attacks, preventing degradation, brittleness, and failure.

PVC Pipes: While PVC material inherently resists many chemicals, standard PVC pipes aren’t optimized for the specific chemical cocktail present in drainage systems. The lack of specialized formulation can potentially lead to accelerated aging when exposed to aggressive drainage chemicals over extended periods.

Winner for Drainage Applications: SWR Pipes offer superior chemical resistance for the specific demands of drainage systems.

4. Installation Requirements and Jointing Systems

SWR Pipes: These pipes utilize jointing systems specifically designed for drainage applications. Rubber ring joints create watertight seals while allowing slight movement to accommodate building settlement and thermal expansion. Solvent cement joints, when used, are formulated for drainage system requirements. The jointing design prevents leakage in non-pressure applications while allowing appropriate flexibility.

PVC Pipes: Standard PVC pipes typically employ solvent cement welding that creates permanent, rigid, pressure-tight joints. While excellent for water supply systems where joints must withstand internal pressure, this rigid connection system is sometimes over-engineered for gravity drainage applications and may not accommodate building movement as effectively.

Winner: Essentially a tie—both systems install relatively easily, but SWR jointing is optimized specifically for drainage requirements while PVC jointing is optimized for pressure applications.

5. Cost Considerations and Long-Term Value

SWR Pipes: The initial purchase price of SWR pipes is generally higher than standard PVC pipes due to specialized manufacturing standards, thicker walls, enhanced chemical resistance, and quality control requirements. However, this higher upfront cost translates to better value in drainage applications through reduced maintenance, fewer blockages, longer service life, and lower repair costs over the building’s lifetime.

PVC Pipes: Standard PVC pipes offer lower initial costs, particularly for basic schedules used in water supply. This price advantage makes them attractive for budget-conscious projects. However, when used in drainage applications, potential performance compromises may lead to higher long-term costs through increased maintenance, earlier replacement, or system failures.

Winner: PVC Pipes for initial cost, but SWR Pipes deliver superior long-term value specifically in drainage applications where their specialized features prevent costly problems.

6. Flow Efficiency and Hydraulic Performance

SWR Pipes: The internal geometry and surface finish of SWR pipes are engineered to optimize flow characteristics for drainage applications. The smooth interior minimizes friction loss, allowing waste and water to flow efficiently under gravity. Larger diameter options accommodate high volumes during peak usage or heavy rainfall. The design prevents debris accumulation that could lead to blockages, maintaining consistent performance over decades.

PVC Pipes: While PVC pipes also feature smooth interiors that reduce friction, they’re not specifically optimized for the unique flow dynamics of drainage systems where solid particles, varying fluid densities, and periodic high-volume slugs create different hydraulic conditions than steady water supply flow.

Winner for Drainage Applications: SWR Pipes deliver optimal hydraulic performance for drainage system requirements.

7. Acoustic Performance and Noise Control

SWR Pipes: Noise transmission from drainage systems can significantly impact building comfort, particularly in residential construction where pipes may run through walls adjacent to bedrooms or living spaces. The thicker walls of SWR pipes provide substantial sound dampening, absorbing much of the noise generated by flowing water and waste. This acoustic performance is especially valuable in multi-story buildings where drainage stacks serve multiple floors.

PVC Pipes: Thinner-walled standard PVC pipes offer less acoustic insulation. The noise of water rushing through drainage pipes can be clearly audible in adjacent rooms, creating comfort issues and potentially reducing property value in residential applications.

Winner: SWR Pipes provide superior acoustic performance, contributing to quieter, more comfortable indoor environments.

8. Environmental Considerations and Sustainability

Both SWR and PVC pipes offer environmental advantages over traditional metal piping. They require less energy to manufacture, don’t corrode and contaminate water or soil, are lightweight reducing transportation emissions, and are recyclable at end-of-life. However, SWR pipes’ longer service life in drainage applications and reduced need for replacements make them the more sustainable choice for waste disposal systems specifically.

9. Standards Compliance and Quality Assurance

SWR Pipes: In India, quality SWR pipes should comply with IS 13592 standards, which specify comprehensive requirements for unplasticized PVC pipes used in soil and waste discharge applications. These standards cover dimensional tolerances, material composition, pressure ratings, impact resistance, chemical resistance, and performance testing. Compliance ensures reliable performance and safety.

PVC Pipes: Water supply PVC pipes should meet IS 4985 standards covering potable water supply applications. These different standards reflect the different performance requirements of pressure water supply versus gravity drainage systems.

When to Choose SWR Pipes: Optimal Applications

SWR pipes represent the professional and technically correct choice when your project requires:

Comprehensive Drainage Systems: All drainage applications in toilets, bathrooms, kitchens, laundry areas, and utility rooms benefit from SWR pipes’ specialized design. The pipes handle solid waste, grey water, and all types of drainage reliably.

Rainwater Management: Rooftop drainage, gutter downspouts, and rainwater harvesting systems perform optimally with SWR pipes designed to handle large volumes of water during heavy rainfall events.

Sewage System Infrastructure: Municipal and building sewage systems benefit from SWR pipes’ chemical resistance, structural integrity, and long-term reliability in harsh underground environments.

Underground Drainage Installation: When pipes must be buried under driveways, walkways, or landscaping, SWR pipes’ structural strength and ring stiffness prevent collapse under external loads.

Multi-Story Building Applications: High-rise residential and commercial buildings benefit from SWR pipes’ noise reduction properties, ensuring comfort for occupants in units adjacent to drainage stacks.

Long-Term Investment Projects: When building quality and decades of maintenance-free service are priorities, SWR pipes’ durability and reliability justify their initial cost premium.

When to Choose PVC Pipes: Optimal Applications

PVC pipes excel and should be selected when your project involves:

Potable Water Supply Systems: Distributing clean drinking water throughout residential, commercial, or industrial facilities is where PVC pipes truly shine, offering pressure capability and corrosion resistance.

Irrigation and Agricultural Systems: Garden irrigation, landscape watering, and agricultural watering systems benefit from PVC pipes’ pressure ratings and cost-effectiveness for above-ground and buried installations.

Swimming Pool and Water Feature Plumbing: The pressure requirements and chemical exposure in pool systems make PVC pipes ideal for filtration systems, return lines, and water circulation.

Industrial Process Piping: Many industrial applications requiring chemical resistance and pressure capability benefit from PVC pipes’ versatility.

Budget-Constrained Water Supply Projects: When initial cost is the primary concern and the application involves water supply rather than drainage, PVC pipes offer excellent value.

Installation Best Practices for Optimal Performance

Regardless of which pipe type you select, following proper installation practices ensures optimal performance and longevity:

Adequate Slope Design: Drainage pipes require proper gradient to ensure gravity flow. A slope of 1-2% (approximately 1/4 inch per foot) is typically recommended for sewage lines, though steeper slopes may be appropriate for rainwater systems.

Proper Support and Spacing: Install pipe supports, hangers, or brackets at manufacturer-recommended intervals to prevent sagging over time. Unsupported spans can develop low spots where debris accumulates.

Avoid Sharp Bends and Fittings: Use appropriate elbows, wyes, and sweeps rather than forcing pipes into sharp angles. Gradual direction changes maintain flow efficiency and prevent blockages.

Accommodate Thermal Movement: PVC materials expand and contract with temperature changes. Provide expansion allowances, flexible connections, or expansion joints in long runs to prevent stress buildup.

Professional Installation: While DIY installation is possible for simple projects, complex drainage systems benefit from experienced plumbers who understand proper techniques, local codes, and system design principles.

Thorough Testing: Always conduct water tests before covering pipes with concrete, drywall, or backfill. Visual inspection during testing can identify leaks, improper slopes, or other issues much more easily than after installation is complete.

Compliance with Codes: Follow local plumbing codes and building regulations, which often specify pipe types, installation methods, and inspection requirements for drainage systems.

The Clear Verdict: Which Is Better for Drainage?

After comprehensive analysis across all relevant criteria, SWR pipes emerge as the unequivocal winner for drainage applications. They’re specifically engineered to handle the unique challenges, chemical environments, and performance requirements of waste disposal and rainwater systems. The specialized design, optimal wall thickness and structural integrity, enhanced chemical resistance for drainage environments, superior acoustic performance, and optimized flow characteristics make SWR pipes the professional choice for all drainage applications.

While PVC pipes are excellent products that excel in water supply and irrigation applications, using them for drainage represents a compromise. It’s analogous to using a multi-purpose tool when a specialized instrument would perform significantly better. The specialized features of SWR pipes aren’t unnecessary luxury additions—they’re essential characteristics that prevent common drainage problems including blockages, noise complaints, chemical degradation, and premature failure.

The slightly higher initial investment in SWR pipes for drainage systems pays substantial dividends through better day-to-day performance, fewer blockages and backups, reduced maintenance requirements and costs, longer service life before replacement, lower risk of failures and emergency repairs, better acoustic comfort in occupied spaces, and higher-quality building infrastructure that adds value.

Conclusion: Making the Right Choice for Your Project

Selecting between SWR and PVC pipes ultimately depends on understanding your specific application requirements and choosing the pipe type engineered for that purpose. For drainage systems—whether in residential homes, commercial office buildings, industrial facilities, or institutional structures—SWR pipes provide the specialized features and performance characteristics necessary for optimal, trouble-free operation.

Their purpose-built design directly addresses the unique challenges of waste disposal and rainwater management, delivering reliable performance that standard PVC pipes, despite their many advantages in other applications, simply cannot match. The engineering that goes into SWR pipes reflects decades of drainage system experience and represents the industry’s consensus on best practices for these critical building systems.

At City One Plymer, we’re committed to providing high-quality SWR pipes that meet and exceed international standards while delivering the reliable, long-lasting performance your projects demand. Our products undergo rigorous quality control testing, comply with relevant IS standards, and are backed by our expertise and customer support.

Whether you’re planning a new construction project, renovating existing facilities, or upgrading aging infrastructure, our team is ready to provide expert guidance on selecting the right pipes for your specific requirements. We’ll help you understand the technical specifications, ensure proper sizing for your application, and support you through installation to ensure optimal results.

Don’t compromise on the critical infrastructure that keeps your building functioning smoothly. Choose specialized SWR pipes for your drainage systems and experience the difference that purpose-built quality makes.

Ready to upgrade your drainage system with premium SWR pipes? Contact City One Plymer today for a comprehensive consultation, technical specifications, competitive pricing on bulk orders, and professional guidance for your project needs. Let us help you build drainage infrastructure that performs flawlessly for decades to come.

Md. Hossain is the Chairman of City-One Polymer Industry Ltd, providing strategic leadership and guiding the company’s long-term vision. With strong business expertise and a commitment to quality-driven manufacturing, he plays a key role in ensuring the company’s steady growth, innovation, and market trust across Bangladesh.